A team of researchers at Korea Institute of Science and Technology, working with a colleague from Korea University, has found that etching grooves onto the surface of face masks makes them better at repelling water droplets and thus more effective at preventing the spread of disease.

In their study, published in Proceedings of the National Academy of Sciences, the group used a well-known etching technique to reduce moisture buildup in face masks used to prevent the spread of infections from airborne diseases.

Prior research has shown that over several hours, an N95 face mask can become less effective due to buildup of moisture from the breath of the person wearing it. This makes it more difficult for air to pass through, resulting in increased pressure inside the mask.

The result of this moisture buildup is more air exhausted from the sides of the mask, potentially releasing more airborne particles into the local environment. Moisture buildup also makes masks less comfortable to wear. In this new effort, the researchers sought a way to expel excess moisture from N95 masks without carrying viruses with it.

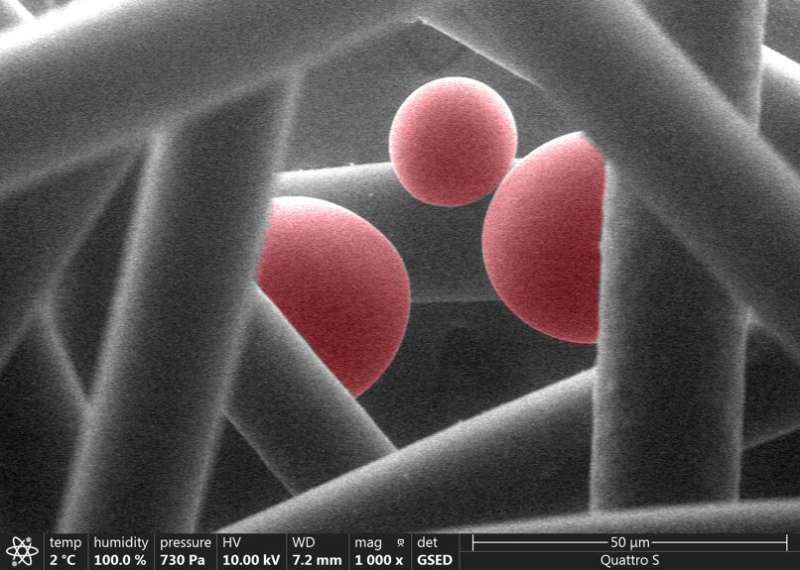

Plasma etching is a mature technology that involves blasting pressurized gas at a material with such force that tiny grooves in the material form. It is generally used to make electronic devices. The resulting material becomes water repellent because the grooves are too small to hold water molecules; thus, droplets wind up resting on pockets of air.

In this new effort, the researchers applied the same technology to both sides of N95 face masks. They found that adding grooves to the front of the mask protected it from rain, mist and other liquid exposures. Inside the face mask, the grooves wicked away breath moisture, preventing its buildup in the mask.

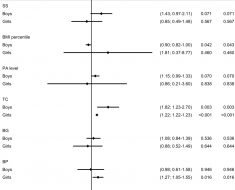

The technique showed significant reductions in moisture buildup with N95 masks in tests. The researchers also found that the grooves repelled microdroplets, which tend to be the carriers of viruses.

The team also tested the possibility of using the technology in a mass production environment by producing 100,000 etched masks in what they describe as a reasonable amount of time. They suggest the next step is to apply the new technology to commercially sold N95 masks going forward.

More information:

Sang Jin Park et al, Multiscale landscaping of droplet wettability on fibrous layers of facial masks, Proceedings of the National Academy of Sciences (2022). DOI: 10.1073/pnas.2209586119

Journal information:

Proceedings of the National Academy of Sciences

Source: Read Full Article